Indirect evaporative chiller

Introduction to indirect evaporative chiller - this equipment is based on one or more national invention patent technologies

Evaporative cooling technology uses unsaturated air to directly contact with water, and water evaporates and absorbs heat, resulting in the reduction of the temperature of air or water.

Evaporative cooling equipment uses this principle to produce cold water or cold air.

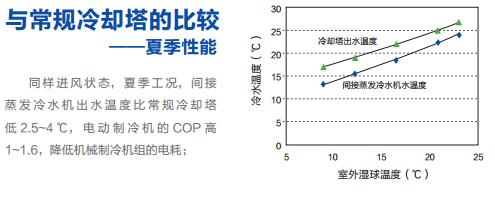

Compared with conventional evaporative cooling technology, indirect evaporative cooling technology can prepare cold water and cold air with lower temperature.

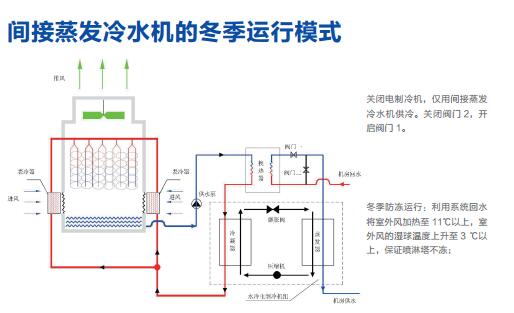

The indirect evaporative chiller is composed of fan and heat exchanger + air cooler + water spray device, etc. the water flows vertically in the tower, and the air flow direction is opposite to the water flow direction. In summer, before entering the packed tower with direct air-water contact, the inlet air is pre cooled by the air cooler. The water of the pre cooled air is the water supply or return water of the cooling tower. In the tower, the spray water contacts with the pretreated air for evaporative cooling to prepare the water supply of the cooling tower.

Four features:

◆ replace the compressor

Indirect evaporative chiller is used for heat removal in tire production. The required cooling capacity is 4000kW. The original traditional cooling is used, and the machine power reaches 800KW / h;

The indirect evaporative chiller is now used. The power of the machine is as low as 150KW / h. cold water of 16-22 ℃ is prepared throughout the year to realize reliable and stable operation throughout the year.

◆ extend free energy utilization time

The traditional cooling mode can use free natural energy for about 2 months every year; Indirect evaporative cooling technology can extend the time of free energy for about 4 months.

For example, in Gansu, Xinjiang and other places, free energy can be used for up to 6-12 months every year.

◆ high efficiency and energy saving

The condensing condition at 28 ℃ is equivalent to the condensing condition at 32 ℃. The efficiency of the refrigeration unit is improved:

1. The efficiency of refrigerator with full liquid evaporator is increased by more than 80%

2. The efficiency of refrigerator with dry evaporator is increased by more than 50%

3. Increase the efficiency of lithium bromide refrigerator by > 40%

◆ antifreeze in winter

Indirect evaporative cooling can circulate hot water all year round at the air inlet to ensure that the temperature at the air inlet is higher than 0 ℃ all year round, which can better play the role of antifreeze.

More Product Displays

More Product Displays

Contact Information

Consulting Service Hotline:4006 336 881

Sales Department I:010-61482380

Sales Department II:010-61482310

Personnel Line:010-61482635

After Sales Special Line:010-61488416

Fax Telephone:010-61482381

Business Cooperation Email:elyxe@elendoo.com

After Sales Service Email:elsh@elendoo.com

Technical Consultation Mailbox:eljs@elendoo .com

Factory Address:Industrial Park, 22 Zhangzhen street, Shunyi District, Beijing

Follow official information

Copyright © Elendoo Technology (Beijing) Co., Ltd. All Rights Reserved. Record Number:京ICP证16067316号

Website Construction:300.cn BeiJing SEO

Your Current Location:

Your Current Location: