Water saving compound closed cooling tower

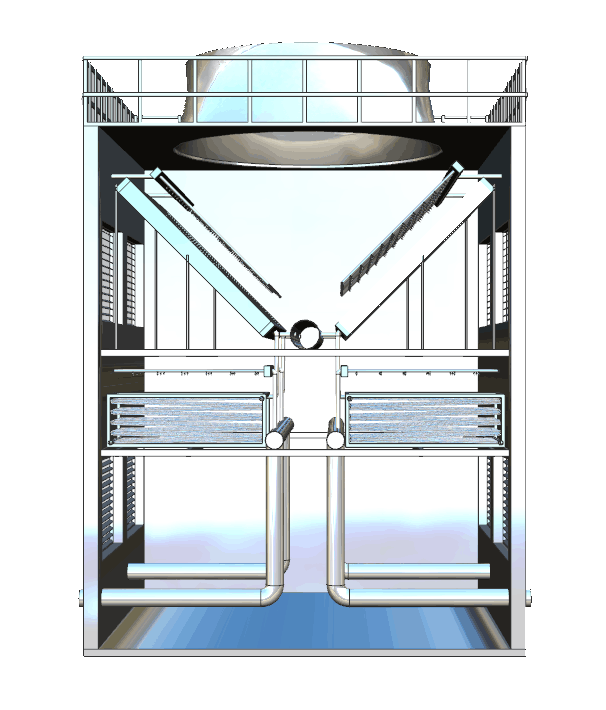

The compound closed cooling tower is composed of finned tube group, water separator, coil group, filler, fan, electric shutter, natural air inlet window, sprinkler system, water tank and water collector. The circulating water and hot water entering the tower will be first released to the cold air by the finned tube group to turn into warm water, and then enter the coil group to release heat to the water and air outside the tube to turn into cold water, and then out of the tower.

The exothermic cooling of circulating water in summer mainly depends on the evaporation of spray water outside the coil; The temperature rise of the wet air after absorbing the evaporated water is small and still lower than the hot water temperature. When it goes up to the finned tube group, it can continue to absorb the heat of the circulating water in the tube, so as to form the best heat exchange process between circulating water and air - countercurrent heat exchange.

When the temperature is low in winter and spring and autumn, the exothermic cooling of circulating water mainly depends on the air cooling of finned tube group; At this time, open the upper electric louver, and most of the fresh air enters the tower directly from the electric louver and flows outside the finned tube to absorb the heat of circulating water in the tube. Because the spraying is stopped, there is no evaporation outside the pipe and no water consumption, so water saving is realized. Since a large amount of cold air does not pass through the coil group below, the corresponding wind resistance is avoided and the power consumption of the fan is reduced. Therefore, the compound structure of finned tube and coil is both water-saving and energy-saving. It is an ideal structure for the closed cooling of large circulating water in the north.

Flow: 5-10000m3 / h

Features: compact structure, simple system maintenance, water saving, reducing or eliminating white fog, year-round operation.

Scope of application: industrial, civil, large temperature difference and water shortage areas.

Product advantages

★ the combination of dry and wet processes can save water throughout the year, and the water saving rate can reach 70%

★ when the temperature is low, the spraying can be completely stopped at 5-15 ℃ and the air cooling operation can be carried out.

★ finned tube U-shaped layout, large slope of coil, smooth layout up and down, can drain water and prevent freezing in winter.

★ the dry and cold part of the finned tube is equipped with electric shutters, which can be opened automatically after the spraying is stopped, with low wind resistance, low energy consumption and energy-saving operation.

★ the finned tube adopts stainless steel tube and aluminum tie, which can be washed with high-pressure water to keep the equipment clean.

★ the coil part adopts 304 stainless steel corrugated pipe, which can automatically descale and ensure efficient operation throughout the year.

More Product Displays

More Product Displays

Contact Information

Consulting Service Hotline:4006 336 881

Sales Department I:010-61482380

Sales Department II:010-61482310

Personnel Line:010-61482635

After Sales Special Line:010-61488416

Fax Telephone:010-61482381

Business Cooperation Email:elyxe@elendoo.com

After Sales Service Email:elsh@elendoo.com

Technical Consultation Mailbox:eljs@elendoo .com

Factory Address:Industrial Park, 22 Zhangzhen street, Shunyi District, Beijing

Follow official information

Copyright © Elendoo Technology (Beijing) Co., Ltd. All Rights Reserved. Record Number:京ICP证16067316号

Website Construction:300.cn BeiJing SEO

Your Current Location:

Your Current Location: